In the global textile industry, woven fabrics (Woven Fabric) have become an indispensable basic material with its excellent strength, breathability and versatility. From clothing to home decoration to industrial applications, woven fabrics have shown incomparable advantages. With the advancement of technology, this traditional fabric is being integrated into modern life in an innovative way, pushing the textile industry to a new height.

Woven fabrics are textiles made by interlacing warp and weft, and their structure and performance vary depending on the material and weaving method. The following are its main features:

The warp and weft interlaced structure of woven fabrics gives them excellent strength and wear resistance, making them suitable for making products that require frequent use or pressure, such as jeans, sofa covers and industrial canvas.

Thanks to the gaps in the weaving process, woven fabrics have excellent breathability and are suitable for clothing that requires comfort, such as shirts, sheets, etc.

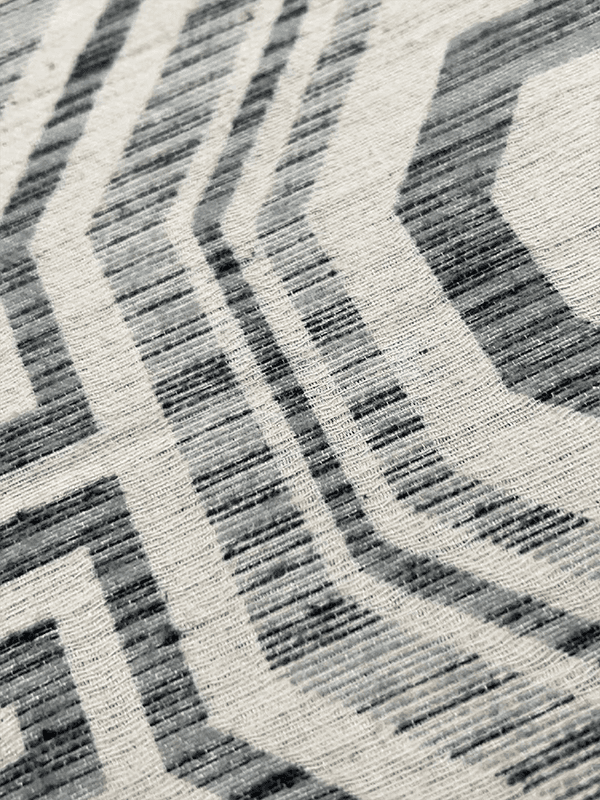

Woven fabrics provide a rich selection of textures, from simple plain weaves to complex twill and satin, which can be achieved through different weaving methods to meet various design needs.

In addition to clothing and home furnishings, woven fabrics also play an important role in the industrial field, such as airbags, filter materials and geotextiles.

Woven fabrics are widely used in clothing, from formal wear to casual wear, and their strength and comfort provide designers with unlimited possibilities. With the rapid growth of the global fashion industry, the demand for high-quality woven fabrics continues to increase.

Consumers pay more and more attention to the texture and personalization in home decoration. Woven fabrics have become the preferred material for sofas, curtains and cushions due to their texture beauty and durability.

In industrial and technical applications, woven fabrics are widely used to manufacture protective equipment, composite materials and engineered fabrics. Their high strength and special functions (such as waterproof and fireproof) are their core competitiveness.

With the increase of environmental awareness, the market demand for environmentally friendly woven fabrics such as recycled fibers and organic cotton continues to rise. This not only provides a growth point for the textile industry, but also meets consumers' expectations for sustainable development.

The integration of modern technology has injected new vitality into traditional woven fabrics.

Automated weaving machines and intelligent manufacturing technologies have significantly improved production efficiency, making the production of complex patterns and high-precision fabrics possible.

The introduction of new materials such as carbon fiber and aramid fiber has made woven fabrics excellent in high temperature resistance and tear resistance, especially in the aerospace and military fields.

Modern technology has made woven fabrics waterproof, anti-fouling, antibacterial and other functions, further broadening their application range. For example, functional woven fabrics are widely used in outdoor clothing and medical protective equipment.

With the help of digital technology, manufacturers can quickly design and produce customized woven fabrics to meet consumers' demand for unique textures and patterns.

Asian countries represented by China and India are the main producers of woven fabrics in the world, thanks to their abundant raw materials, mature production processes and low labor costs. However, these countries are also gradually transforming to high-end manufacturing to meet the quality needs of the global market.

With the development of emerging market economies such as Africa and South America, the demand for woven fabrics in these regions is growing rapidly, especially in the fields of clothing and infrastructure construction.

Globally, consumers and companies are pushing the textile industry to develop in a more environmentally friendly and sustainable direction. Woven fabric manufacturers are accelerating the adoption of environmentally friendly materials and energy-saving processes to achieve circular economy goals.

As a basic product in the textile industry, woven fabrics still have broad market prospects. In the future, its development will be driven by the following aspects:

Artificial intelligence and machine learning will further optimize the production process, improve efficiency and reduce costs while ensuring the stability of product quality.

From fashion to architecture, woven fabrics will play an important role in more fields, providing a broader space for innovative design.

By increasing consumers' awareness and understanding of woven fabrics, brands can further promote the dissemination of their value.

In the future, environmentally friendly woven fabrics using bio-based materials and recycled fibers will occupy a larger market share and help the industry move towards green development.

As an important part of the textile industry, woven fabrics combine traditional craftsmanship with modern technology and continue to innovate and develop. Its wide application in clothing, home furnishings and industrial fields has not only improved people's quality of life, but also injected new vitality into the textile industry. In the future, woven fabrics will continue to occupy an important position in the global market and become an important driving force for the sustainable development of the textile industry.

English

English 中文简体

中文简体 Español

Español عربى

عربى